Got capacity? How much of it is being wasted—or, rather, misused?

Let me help you answer that question.

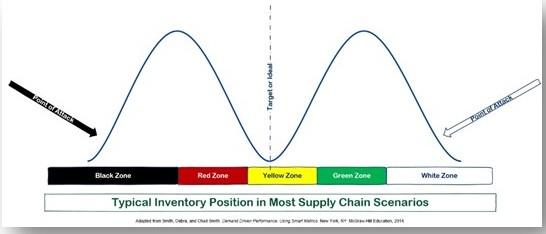

Bimodal Inventory Distribution – A Common Malady

I don't care where we go, or the size of the enterprise with which we are working, the most common situation we encounter is expressed in the accompanying figure, and in the following statement:

"You know—the biggest problem we have (all the time!) is that we seem to have too much of the wrong stuff and too little of the right stuff.

While the goal of every supply chain and every supply chain manager may be summarized by having the right quantities of the right items at the right place at the right time, the failure to do so is nearly ubiquitous in almost every industry.

You've Got Capacity!

If you have "too much of the wrong stuff" on a consistent basis then, in some odd way of thinking, this is actually a good sign!

Why?

Because having excess inventory is evidence that you have capacity to produce stuff in your supply chain.

The problem is that you're just producing the wrong stuff.

The Flow of Relevant Information and Relevant Materials

Having too much of the wrong stuff and too little of the right stuff means that you probably do not have a capacity problem in your supply chain.

It definitely does mean that you have a signal or information problem in your supply chain.

Having too much of the wrong stuff means that your supply chain is sending signals to produce the wrong stuff—or, at least, to produce it at the wrong time. Signals that tell your supply chain to produce the wrong stuff or at the wrong time means that you have irrelevant information flowing in your supply chain.

When you have irrelevant information flowing in your supply chain's information infrastructure, you will get two results:

- The flow of too much irrelevant materials (read: the wrong stuff), and

- The lack of flow of relevant materials (read: the right stuff)

Two Things that Must Change

In order to correct this situation, we have found that two things absolutely must change—and, in this order:

- How the supply chain managers think and measure in determining actions and priorities

- Where and how they get their signals that drive actions and priorities

In case you haven't noticed, the methods that were pretty effective ten or twenty years ago are now almost universally obsolete. That why new thinking and new metrics absolutely must supplant the current way of thinking (in most supply chains) before significant and lasting progress can be made with regard to the flow of relevant materials.

If you tired of fighting—and, fighting again—the same old supply chain battles and fires you have been struggling with for that last five, ten, 15 or more years, we can help you start thinking differently for lasting improvement in your supply chain's performance.

Webinar Replay: Hidden Costs of Inventory Spreadsheets