There is lots of confusion about what a "demand-driven" supply chain really means. So, let me say from the outset that becoming demand-driven does not necessarily exclude the use of forecasts. Neither does demand-driven refer to being make-to-order (MTO).

In a demand-driven environment, forecasts are frequently be used to drive certain parameters. But, once those parameters are set, and are being dynamically maintained, all production is then driven based on actual demand and its effect on the buffers in the supply chain. In demand-driven environments, buffers may be of three types:

- Stock buffers

- Capacity buffers

- Time buffers

Each of these buffers provide their own integral metrics and action signals.

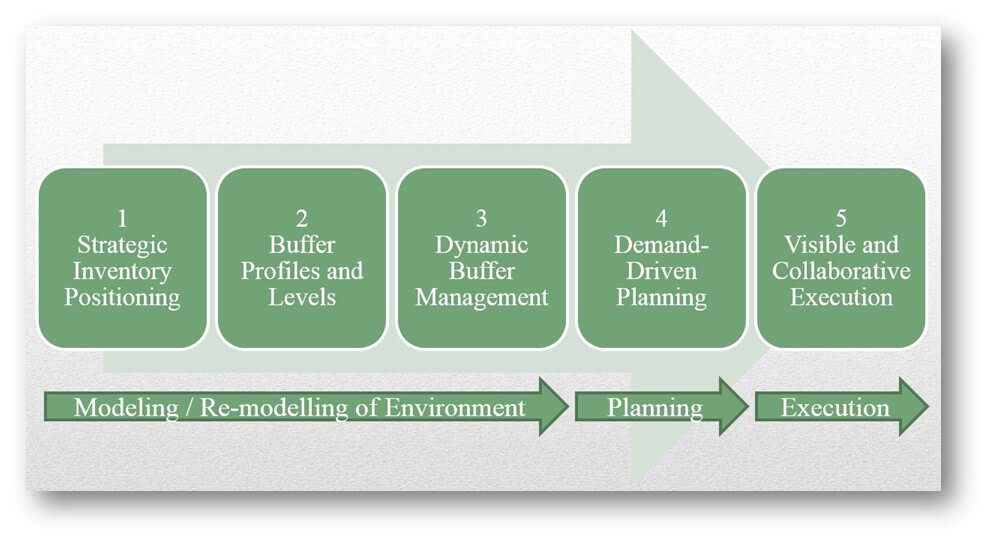

However, today we want talk briefly about the steps toward creating and maintaining a demand-driven supply chain.

Step 1: Strategic Inventory Positioning

Inventory (stock) buffers are strategically positioned in your supply chain if, and only if, the inventory does each of the following three things:

- Absorbs variability – that is, variability in supply, as well as variability in demand

- Decouples lead times – simultaneously shortening lead times to within customer tolerances and reducing the planning (time) horizon for each level in the supply chain

- Provides real (calculable) return on investment – each SKU-Location (SKUL) should provide an ROI that supports its calculated target inventory level (Note: these may change over time and must be dynamically managed)

In order to accomplish strategic inventory positioning, it is necessary to model and understand the flow of goods end-to-end across your supply chain. Whether you choose, or are able, to model your entire supply chain, or simply the portion of the supply chain for which you are responsible, this model must be understood before it is possible (even theoretically) to become truly strategic about managing your inventory.

Step 2: Establishing Buffer Profiles and Levels

In the absence of a clear and rational set of business rules by which buffers are sized and managed (dynamically), it is impossible to even know what the target inventory level is, or should be, for any given SKUL. And, if you do not have a way to know what the target inventory level should be for each SKUL, it is impossible to strategically manage your inventory levels or to calculate the ROI for carrying any given SKUL. (And, of course, if you do not know the ROI for each SKUL, it is—by definition—impossible to know the ROI of your aggregate inventory, either.)

Buffer profiles are merely ways to group individual SKULs so that they can be managed by group profiles. It is, for example, to manage ten groups of about 3,000 SKULs each, than it is to manage 30,000 SKULs individually for many aspects of supply chain management.

Generally, we suggest groupings by the following classifications:

-

Type

- Make (manufactured or assembled)

- Buy (materials purchased for use in manufacturing or assembly)

- Distribute (items purchased for resale, but not generally consumed in manufacturing or assembly)

-

Variability in Supply and / or Demand

- Low

- Medium

- High

-

Lead Time

- Short

- Medium

- Long

- Minimum Order Quantity (MOQ)

A given item SKUL might then be classified as, for example, a Make item with high variability and medium lead-time (and no significant MOQ).

Step 3: Dynamic Buffer Management

It is insufficient to strategically position your inventory (or other buffers) in the supply chain, set the buffer sizes, and then believe that the system should run fine from now on. This should not be, and (in my opinion) cannot be, a set-it-and-forget-it proposition. There must be some level of dynamic control over the established buffers. That is, buffers should be dynamically resized based on the flow of relevant information and materials through the system. As patters of supply and demand change, so should the sizes of the strategic buffers you have placed in your supply chain.

Additionally, there should be a process of ongoing improvement that has the obligation to identify changes in the supply chain that are likely to affect strategic positioning factors. Such changes might be product, model or design changes; changes in vendors; market changes; and so forth.

See Also: What is Dynamic Buffer Management?

Step 4: Demand-Driven Planning

Once you have completed steps 1 through 3, you are ready to implement demand-driven planning. Demand-driven planning is nothing more than using the feedback, alerts and reporting metrics on the status of your stock, capacity or time buffers as the guide for actions. On a routine basis, those actions would be the creation of replenishment orders (e.g., purchase orders, transfer orders, production orders).

Step 5: Visible and Collaborative Execution

On a less routine basis, highly visible alerts might trigger actions including the review of a situation that is not yet critical, but is showing some possibility of becoming critical in the near future; or expediting, in rarer cases.

Collaborative execution, however, points to the fact that, once changes in strategic buffers are made highly visible across the supply chain, addressing changes will, in many cases, involve a cross-functional team. When a dramatic change is signaled by a demand-driven alert, parties from sales, marketing, manufacturing and purchasing might all be involved in identifying what externals triggered the unexpected change, and what the appropriate actions should be to keep the system flowing and profits maximized.

Don't Take Shortcuts

We don't believe there are any real shortcuts to becoming demand-driven.

By that, we don't mean that it cannot be accomplished in a relatively short period of time. For many companies, dramatic improvements might be visible within 90 to 120 days. However, we do mean that you cannot expect dramatic results if you try to do only steps 2 and 4, for example. Chances are the results from such shortcuts will be small and the level of frustration across your organization will be high.

#########################################

How are you working toward becoming demand-driven? What steps have you taken in the last year or two in this direction?

We invite you to leave your comments below, or contact us directly, if you prefer.

CREDITS: This material was extracted and adapted from a great book that I highly recommend--

Smith, Debra, and Chad Smith. Demand Driven Performance: Using Smart Metrics. New York, NY: McGraw-Hill Education, 2014.

[feature_box_creator style="1" width="" top_margin="" bottom_margin="" top_padding="" right_padding="" bottom_padding="" left_padding="" alignment="center" bg_color="" bg_color_end="" border_color="" border_weight="" border_radius="" border_style="" ]

Demo Replay: Sage Inventory Advisor

Want to learn more about Sage Inventory Advisor? In this webinar we will break down the key components of Inventory Management.

Replay on RKL YouTube Channel

<

[/feature_box_creator]