We are continuing our discussion of Gene Tyndall’s white paper for Tompkins International “Demand-Driven Supply Chains: Getting It Right For True Value” [Tyndall, Gene. Demand-Driven Supply Chains: Getting It Right for True Value. White Paper. Raleigh, NC: Tompkins International, 2012. Print.].

In his white paper, Tyndall mentions CEO Jim Tompkins’ book entitled No Boundaries: Moving Beyond Supply Chain Management, originally published in 2000. For its time, it was certainly a visionary work.

No Boundaries : Moving Beyond Supply Chain Management: James A., Ph.D. Tompkins: 9780965865920: Books No Boundaries : Moving Beyond Supply Chain Management: James A., Ph.D. Tompkins: 9780965865920: Books |

According to Tyndall, the book describes six levels in the evolution of “supply chain excellence.” There is still much truth to these more than a decade after Tompkins laid them out for us. Here they are as described in No Boundaries:

Level 1: Business as Usual. At this level, a company works hard to maximize its individual functions. Organizational effectiveness is not the focus. Instead, each organizational element attempts to function well on its own. Each division/department applies its own strategy for applications used.

Level 2: Link Excellence. Now, the link eliminates and blurs any boundaries between departments and facilities, and begins a never-ending journey of continuous improvement. Its individual link must evolve to make it the most efficient, effective, responsive and holistic that it can possibly be.

Level 3: Visibility. Links work better when they share information. Visibility establishes the groundwork for information sharing. It minimizes supply chain surprises because it provides the information links need to understand ongoing supply chain processes.

Level 4: Collaboration. Collaboration is achieved through the proper application of technology and true partnerships. Through collaboration, the supply chain can determine how best to meet the demands of the marketplace. The supply chain works as a whole to maximize customer satisfaction while minimizing inventory.

Level 5: Synthesis. Synthesis is a continuous improvement process that integrates and unifies a supply chain. Synthesis harnesses the energy of change to address a turbulent marketplace and ensure customer satisfaction. It is from synthesis that true Supply Chain Excellence is achieved because it enables a supply chain to reach unparalleled levels of performance.

Level 6: Velocity. The goal becomes accelerating the organization or supply chain to a higher velocity. Velocity creates shorter time frames, and this begets demand-driven.

Tyndall adds to these six levels of supply chain evolution an apparent seventh, taking us into the world of truly demand-driven supply chains (DDSC), when he says:

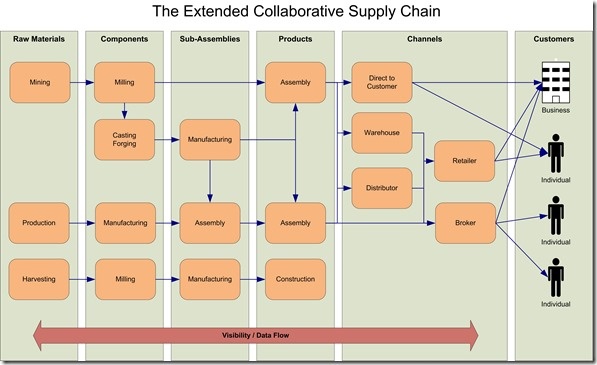

Demand-driven takes customer purchase information at the point of sale (POS) and provides it in real-time to all trading partners throughout the end-to-end supply chain. This means the entire supply chain sees one set of sales numbers and responds to those numbers in real-time. The key success factor of demand-driven is the timeliness of the data reflecting real transactions.

I have previously depicted what Tyndall describes. See “The Extended Collaborative Supply Chain” illustration below.

Thus far, Tyndall and I are very much in agreement. However, he throws the proverbial “monkey wrench” into my train of agreement with him when he opines on “the importance of sales and operations planning (S&OP) in demand-driven” supply chain operations.

Wait a minute! Did not this same author tell us (see my previous post “On Demand-Driven Supply Chains”), “Companies are facing new and unprecedented business challenges and trying to solve them with outdated tools and practices, which worked well (for some) in the past, but are not equipped to deal with the degrees of volatility, uncertainty, and complexity of today’s world.” [Emphasis added.]

Now, a few paragraphs later, this same author is trying to tell us that “[a]t the heart of the new demand-driven operations strategy is the sales and operations planning (S&OP) process,” which he admits was originally created “some 20 years ago… to obtain collaboration around sales forecasts.”

Are these the same forecasts against which he had just levied this accurate charge?

Most forecasting models are based on assumptions that do not cooperate with complex current conditions, such as: (1) that behavioral observations are truly independent, and (2) that it is very likely that we extrapolate average responses. Neither is true in today’s complex markets; no degree of past business intelligence is adequate for predictive purposes.

Now I am anxious to discover what has led to this thinking by Mr. Tyndall, and it does not take long to uncover where, I believe, he misses the mark.

In one sentence, Tyndall offers up the very cogent truth that plagues so many good-hearted supply chain managers and executives:

Collaboration is easier to discuss than to execute, products have proliferated, and volatility and uncertainty have predominated.

Attempts to Balance Demand and Supply

Unfortunately, Tyndall comes to the same wrong conclusion that so many have come to in seeking a demand-driven supply chain. Tyndall (at least on page seven of his paper) is still advocating attempts to balance “demand and supply” and finding that “profitability” elusive in doing so.

This will always be the case. Profits will falter in attempts to balance supply with demand for two elemental reasons:

- Demand volatility

- The inevitability of the attacks of “Murphy”

-

Attempts to balance supply with demand almost always lead to minimizing or eliminating what supply chain managers and executives see as “excess capacity” when, in fact, most of what is being eliminated is not “excess capacity,” but “reserve capacity.”

Excess capacity is capacity that is never needed by the system under present operational circumstances. Reserve capacity, however, is something entirely different. Reserve capacity is the capacity every system needs in order to recover from the occasional—but, nevertheless, inevitable—attacks of “Murphy.”

When reserve capacity is reduced, supply chain agility is reduced, as well. As a result, supply chain risk grows. Supply chains without reserve capacity will suffer reduced profitability from both sides:

- Too much inventory—leading to excess carrying costs, liquidations and obsolescence

- Too little inventory—leading to lost sales, lost customers and increased marketing costs as efforts are made to retain existing customers and attract new ones

The Right Answer: Balance the Flow with Demand

The proper answer to Tyndall’s well-stated dilemma is the truly demand-driven supply chain—a supply chain where the flow (not the supply) is balanced with demand. Balancing the flow is achieved using the same principles we have so frequently discussed before:

- Reduce batch sizes – work toward the reduction of both the production batch sizes and the transfer (shipment) batch sizes

- Increase replenishment frequency – start by trying to cut your replenishment frequency by one-third or one-half

- Provide near real-time feedback – work toward the ideal of end-to-end real-time feedback on actual consumer demand all across the supply chain

- Build collaboration on Throughput – it is much easier to build durable supply chain collaboration on increasing everyone’s profits and profitability than it is on cost-cutting

When supply chain executives and managers recognize the need to balance flow with demand and quit trying to balance supply with demand, they will begin to find greater success and improved profitability. Pursuing these four simple principles (above) will move every supply chain in the right direction while simultaneously reducing the levels of risk in the supply chain for all participants.

Please let us hear your thoughts on this topic. Feel free to leave your comments here, or you may contact us directly.