There is not shortage of articles about getting the most out of your ERP system (Enterprise Resource Planning). My Google search on this topic returned more than 1.66 million results in 0.36 seconds.

The problem is that too many of these articles are written by VARs (value-added resellers) and consults with a predetermined agenda. They have a technology or a service or a solution to sell to their readers.

And, even for those that do not have "a package" to sell, too many have a "cookie cutter" approach to consulting.

Like one of the "Seven Habits," (practiced in a bad way) they are likely to arrive at your doorstep "with the end in view." And, while such "one-size-fits-all" approaches may give some small return on your investment, the benefits are far more likely to provide short-lived and incremental improvement, not far-reaching or delivering a sustainable competitive advantage for your enterprise.

This comes to mind because I recently read an article online about "getting the most out of your ERP system." The article was written by someone promoting a ADMS (automated document management system) as an add-on for ERP systems.

Now, don't get the wrong idea here.

I am not opposed to ADMS add-ons. I've even recommended them to my clients from time to time over the years.

What I am opposed to is jumping to the conclusion that "more automation" and "increased efficiencies" in some department or even a few departments equates to "getting the most out of your ERP system."

Getting the most out of your ERP system isn't the point

Getting "the most out of your current ERP solution" isn't the point. The essential thing is to "get the most out of your entire system," meaning getting the most out of the entire flow of steps and processes that lead from customer acquisition (sales and marketing) to booking the profits on the bottom-line. This is true "system thinking."

That means that, in order to strengthen the chain, you must strengthen ONLY the weakest link. Strengthening any other place in the chain adds only "weight" (e.g., complexity, additional operating expenses) and requires investment of the companies most precious resources: time, energy and money.

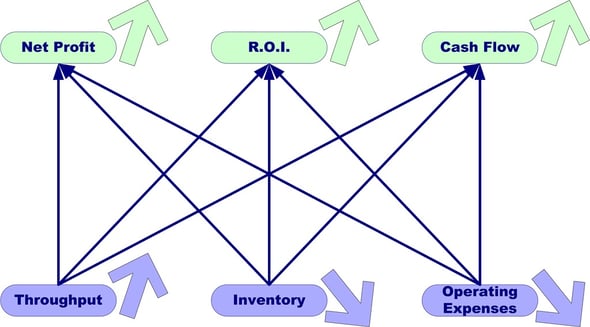

When we want to help the companies with whom we work improve (read: make more money), we guide them through a process to help their executive and management team discover those very few those things that need to change in order to have the desired effect on the following key metrics (and in this very specific order):

- INCREASE Throughput (where Throughput is defined as revenues less only truly variable costs--or TVCs)

- REDUCE Investments--including reductions in inventory, but also delaying or eliminating entirely the need for new capital investments in buildings, equipment, and technologies

- SLASH Operating Expenses (where these are defined as all the money paid out month after month that are NOT included in TVCs or Investment) - or - hold the line on Operating Expenses while sustaining significant growth in Throughput (say, 30 to 300 percent growth)

Many times our advice to clients is actually to not spend money on new technologies until they have exhausted improvements that require no new investment of any kind. This advice frequently stems from improvements designed around inherent simplicity--the concept that simple solutions are the best way to solve complex problems.

Calculating POOGI Project ROI and determining project priorities

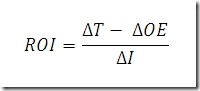

Furthermore, we help the executives and managers prioritize every improvement option on the basis of this simple equation for POOGI (process of ongoing improvement) ROI:

This formula is read as:

ROI (return on investment) = (delta-T - delta-OE) / delta-I

Where:

- delta-T = change in Throughput

- delta-OE = change in Operating Expenses, and

- delta-I = change in Investment

If delta-I is zero for some, then those POOGI projects should be considered first, and they should be prioritized based on (delta-T - delta-OE) in descending order. This approach places those projects most likely to increase profits and improve cash-flow at the very top of the priorities list.

Using this approach, we have help some organizations discover and enact dramatic improvements in their operations, or even across their supply chains, that cost them virtually nothing and could be implemented in a matter of days. No "cookie-cutter" here! Each POOGI concept was the invention of the management team assembled and they determined its value and how, when and why it should be implemented.

The very real side-effect of this approach is that there is seldom anyone who remains skeptical of the solution or is likely to try to sabotage the implementation of the improvement. Instead, eagerness abounds.

Every POOGI project should have expected and measurable outcomes (no "pie in the sky")

Every project should have EXPECTED (estimated) and MEASURABLE outcomes and these values should be measured before and after the POOGI project implementation.

To be even clearer: NO PROJECT should be undertaken with a NEGATIVE delta-T - delta-OE values, nor should any project be undertaken that has a POSITIVE delta-I with a ZERO delta-T - delta-OE value). Such projects have a negative ROI.

Simply pouring in new technologies in "hope" that somehow the technologies will produce some expected "rule of thumb" result provided by the VAR, or even your IT staff.

If your management team cannot estimate a positive ROI and explain how the POOGI will contribute specifically to the estimated changes in T, OE and/or I, then chances are no real ROI exists for the project.

We call this approach "The New ERP -- Extended Readiness for Profit." It works within the four walls of an organization, but its powerful concepts can be leveraged to help re-engineer entire supply chains, as well.

We would like to hear about your experiences with improvement projects and how you prioritize such projects and measure their outcomes. Please leave your comments here or, if you prefer, contact us directly.

[feature_box style="2" only_advanced="There are no title options for the choosen style" alignment="center"]

While You're Here ...

While You're Here ...

Grab a copy of The 8 Sins of ERP Project Failure.

This free guide provides insights about how to avoid common mistakes and ensure a successful ERP implementation.

Download Free Guide [/feature_box]