Over the last few decades, companies of all sizes have spent (cumulatively) billions of dollars on ERP (enterprise resource planning) systems, traditional MRP (material requirements planning) systems, advanced forecasting systems, and supply chain operational enhancements. The goal, presumably, in all of these expenditures of time, energy and capital, was ROI (return on investment).

The promise of ERP and traditional MRP systems was that better information would lead to lower inventory investments, thus freeing up cash for other uses in the enterprise.

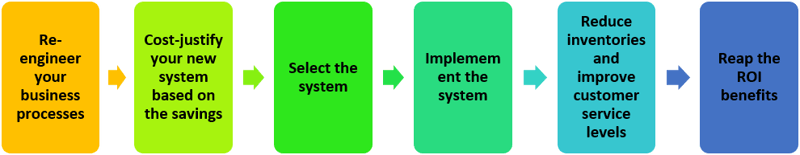

QUESTION: How is that working out for you? If you look back over the last decade or two, are you seeing real payback from your investment, or are you just squeezing out the results of organic growth in your business and the economy? The investments in ERP and traditional MRP systems were supposed to make the company more responsive to current and future customer demand, reduce the costs of carrying inventory (as a direct result of reduced inventories) and minimize inventory obsolescence. It was supposed to be straightforward, and work something like this:

New Software without New Thoughtware

Unfortunately, the BPR (business process re-engineering) that occurs with most ERP and traditional MRP implementations simply involves learning new processes around how the software works. The traditional MRP/ERP processes tend to institutionalize and automate existing processes without changing how people really think.

Traditional MRP/ERP implementations generally make no provision for addressing what happens in your S&OP (sales and operational planning) processes, or between operations and finance, or operations and sales. So, all of this remains pretty much unchanged in reality, even though there are generally huge expectations for change in the outcomes.

However, the interactions in your S&OP processes and the interactions between sales, finance, and operations involve a very complex set of inputs, outputs, and decisions. These are complicated by the fact that people in different departments see the same things in very different light—not to mention the fact that different departments and positions are typically measured in different ways. And the ways the different departments are measure may even be in conflict when it comes to achieving the goal of the entire system (ROI).

People will virtually always make decisions that will maximize their returns—but it will be their returns, not necessarily the company’s returns. For example, if I receive incentives to reduce inventories, I can do that. Nevertheless, those inventory reductions may very well be achieved at the cost of lost sales, or even lost customers.

Excuses for Too Much Inventory

- Not Getting Pounded On – “Hey! If I run out of this stuff, I get really pounded on by the sales (or ‘production’) people. But, if I have too much, I only get a little barking at from the finance folks—and, from them, it’s non-specific and only happens once a quarter to so.”

- Talk to the Front Office Guys – “The sales folks are just too optimistic! Sometimes I have trouble even believing their numbers. I know. I know. Their metrics make it hard for them to tell management that they don’t expect to actually meet the goals set by finance. But, does anybody really understand the cost of buying and producing all this stuff that we’re not going to sell? You know, I can’t risk not buying or producing what sales says they want. It’s not my problem that we’ve got too much of the wrong stuff!”

- More metrics than the IMF – “I’ll tell you what: this company has more metrics than the International Monetary Fund! Arguments between departments and divisions are way too commonplace. It’s simply impossible to make all the metrics go in a positive direction all at the same time! Even for me! I’m told to keep my inventory down, but I get measured on ‘cost per unit’ and ‘utilization rates,’ so cutting production only hurts my performance numbers.”

- Big batches are less work for me – “Being flexible just means more work for me the way we do things around here. It’s a real disruption to shift gears, clean up, and make smaller batches. I like big batches. It just less work for me, and my coworkers.”

- Our problem is apathy, but who cares? – “We always have too much inventory. I’ve been working here for years and we’ve always had too much of the wrong stuff lying around. Sure, people talk about fixing it. But, all the efforts we put into putting out fires on a daily and weekly basis are the important thing, so dealing with ‘excess inventory’ takes a backseat again and again.”

- But, the EOQ tells me to buy this much – “Who knows what EOQ really means or how it’s calculated? All I know is that our ERP system tells me to buy this much stuff. Besides, my key metric is ‘unit cost,’ so I’m all in for buying in big lots and get the lowest unit-costs I can.”

No Excuses for Bad Performance

Chances are you’ve heard some of these excuses before. If you have, you’ve probably heard them on more than one occasion.

But, there is a way to become truly demand-driven and reap the benefits of

- Dramatically reduced inventories (perhaps as much as 40 percent or more)

- Sustained and improving high levels of customer service

- Virtual elimination of finger-pointing and blaming between departments and functions

- Restored employee morale and reduced employee turnover

- Slashed costs related to expediting and fire-fighting

- Rapid ROI on the time, energy and capital invested in making the changes