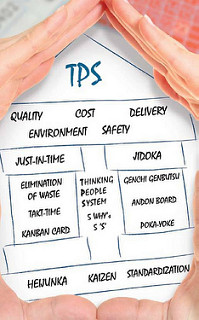

The Toyota Production System (TPS) -The Pillars of TMHE (Photo credit: Toyota Material Handling EU)

More than 50 years ago, in Nagoya, Japan, Taiichi Ohno and his team at Toyota began quietly perfecting what has come to be called the Toyota Production System (TPS). It has also come to be called Lean production. While it is widely known as a collection of tools including kaizen, kanban, andon and more, the real article—the Toyota Way—is not a set of “tools” at all. It is a deeply held philosophy for doing business that leads to a culture that can—and frequently does—extend beyond the four walls of the firm itself.

The genius of TPS—the system that has made a post-WWII, nearly destitute company a worldwide leader in the automotive industry—is that Toyota recognized two key things:

- You can’t build a lasting house without a carefully laid foundation; and

- A house is for people—people are at the center and heart of the house.

Building on a Sound Foundation

Lean has certainly been the most far-reaching management concept to be brought forward in the last 50 years. And, at the foundation of the TPS “house” it is a long-term philosophy that guides each action.

It is this underlying philosophy and long-term view which provides a sense of purpose that guides and governs short-term decision-making. This keeps the whole organization—the whole system—working and growing toward a common purpose.

The company focused first on creating value for its customers will tend to automatically generate value for the society and the economy in general. The value generated for the customer becomes the ultimate measure for every action and function carried out within the company.

Trusting the People in the House

Operating within this foundational principle, the people in the Toyota house are then encouraged to be responsible and self-reliant, trusting in their own abilities and insights. This enables workers to contribute to their highest potential—to bring to their work all that they have to offer.

This stands in stark contrast to the philosophy that we too frequently hear expressed (or, at least, tacitly acknowledged) by owners, executives and managers in companies to whom we are introduced. Probably the worst case I ever came face-to-face with was when consulting for a young and successful entrepreneur some years ago in El Paso, Texas.

On more than one occasion, this young CEO said to me, “Everyone who works for me is an idiot.”

After hearing this repeated several times over the course of a few weeks in our meetings together, I finally said, “Well, I guess that makes you the Chief Idiot, since you are the one who hires these people, pays their wages, and keeps them around.”

He looked up at me somewhat dumbfounded—but he got the point: either you trust the people in “the house you’re building,” or you do not. If you genuinely do not trust them, then you ought to get rid of them and get people you and can and do trust.

Giving Meaning to the Work Being Done

My experience has been that almost all employees want to do a good job for their employers. There are very, very few truly “bad apples” in the crowd. The vast majority recognize that their continued employment at their present job depends upon the company continuing to make money.

However, managers and executives frequently send mixed signals in their communications to their employees.

Not long ago, an executive management team asked me: “How can we keep employees from taking shortcuts that cause the data in our ERP system from being accurate?”

This was one of those cases where valueless complexity was gumming up the works. All too frequently the workers where forced to make a no-win decision: Do I serve the customer’s needs, or do I serve the demands of the ERP system? They were frequently choosing the former over the latter. (An excellent choice, in my opinion.)

Here’s what I told the CEO and the executive management team:

“I firmly believe that your employees want to do the right thing. But, right now, the complexity of your systems is forcing them to make a choice. On the one hand, you have made it clear to them that a first priority is to ‘serve the customer’—get the orders out the door. On the other hand, you have made the workers equally aware that you are very displeased when the ERP system’s inventory gets ‘screwed up’ because the data entry isn’t complete or on-time.

“Your employees are making, it seems, the very decision that—in your heart of hearts—I think you really want them to make. They are choosing to serve your customers’ interests and taking action to get the products produced and shipped, even if it means working around the ERP system to get it done.

“Remove some of the valueless complexity with which you have burdened them and you will give these workers a real sense of meaning in their efforts to serve your customers. Plus, they won’t have to struggle with the ongoing moral dilemma of which of your mandates they should obey day after day.”

If You Ask Them…

Generally, the front-line workers are very much aware of valueless complexity. They may even have tried to speak up when such complexity was foisted upon them.

But the edict had come from on-high: “This is how the work must be done from now on.”

Toyota has built more than 50 years of success and become a world-class company because they believe that “no one knows more about the machine than the man running the machine.” They have learned to listen to “the people in the house,” and learned, thereby, to constantly cut away at valueless complexity in the process of delivering a winning customer experience.

We have learned that unlocking “tribal knowledge”—learning once again to listen to all the people in the house you and your management team are building—is the fastest way to begin a successful process of ongoing improvement (POOGI).

The same thing applies, by the way, to listening to all of the participants in your supply chain. Listening to your supply chain partners—up and down the supply chain—can bring, not only dramatic improvements in performance, but also dramatic reductions in risk.

Think about it. What is your company’s philosophical foundation, and how are you building a house for people on that foundation?

We would like to hear what you have to say on this important topic. Please leave your comments below, or you may contact us directly, if your prefer.