Today's companies need to utilize and maintain their equipment to get the best return on investment. One way to do that is by having a software solution that provides greater visibility into operations and maintenance. Sage X3 now provides the Preventive Maintenance solution to plan and process maintenance operations of physical assets in your organization. This solution will help reduce inefficiencies, improve productivity, optimize inventory levels, and reduce purchasing costs.

The result? Increased profits.

![]()

Functions of Preventive Maintenance in Sage X3:

equipment management

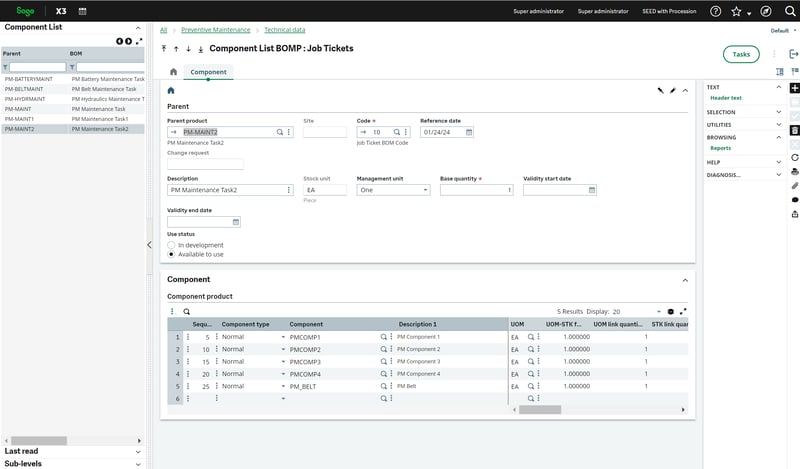

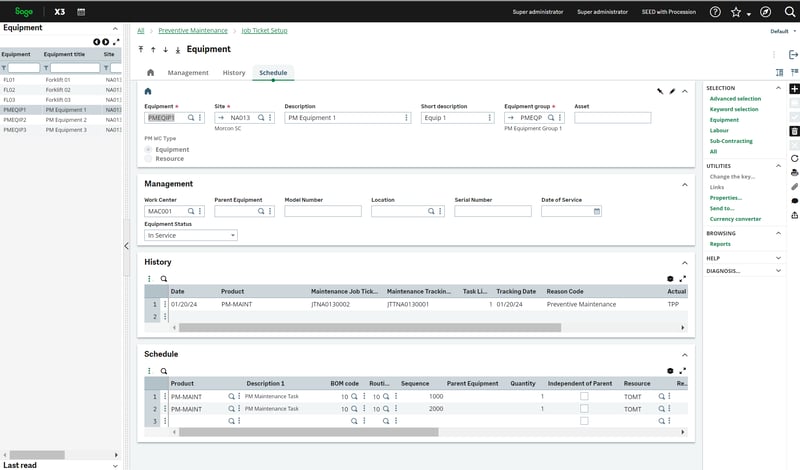

Integrating detailed product and Bill of Materials (BOM) information into the maintenance process allows you to track and schedule maintenance tasks, identify potential issues before they escalate, and ensure that equipment is operating at peak performance levels. This reduces downtime and costly repairs and streamlines maintenance operations for increased productivity and cost savings.

resource management

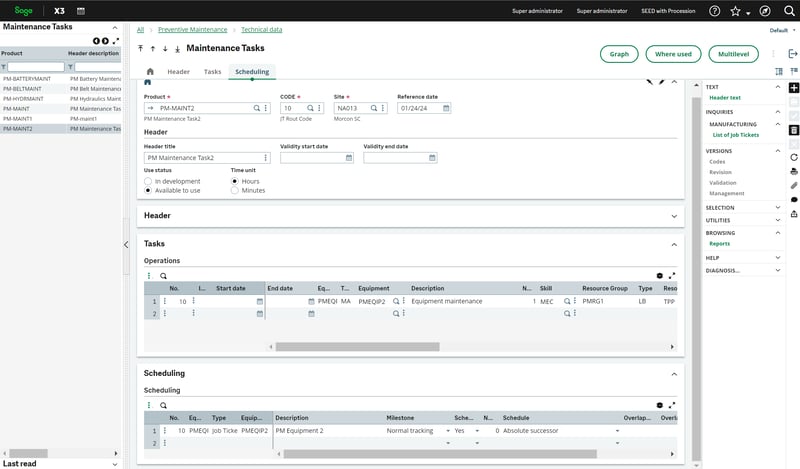

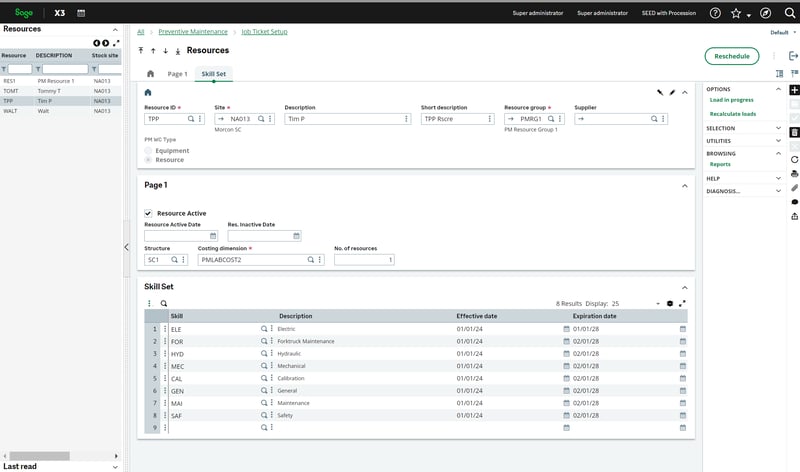

Within the preventive maintenance solution, you can precisely schedule maintenance activities for your equipment and other resources. By utilizing the calendar feature, you can streamline the process of managing equipment maintenance schedules, ensuring that tasks are completed in a timely manner and resources are utilized effectively. This level of organization and planning minimizes downtime and productivity, ultimately leading to cost savings and increased profitability for your organization.

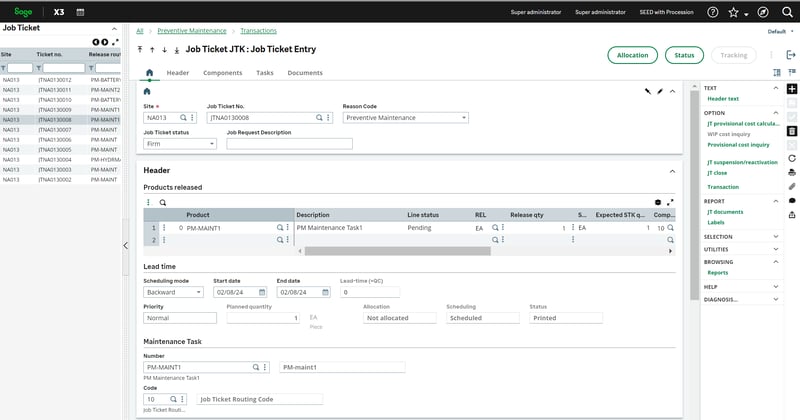

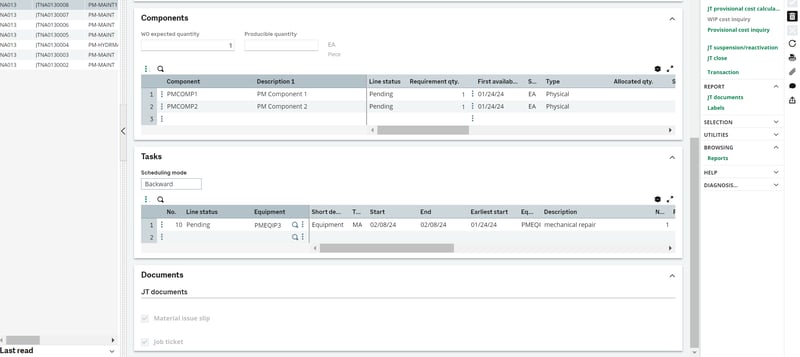

job ticket management

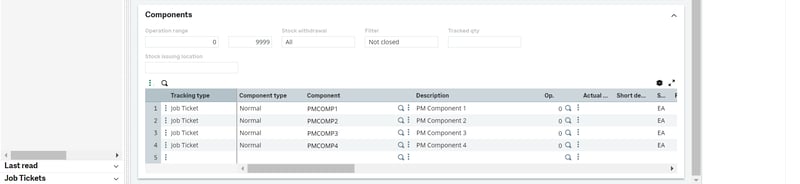

The job ticket management function categorizes work orders based on whether they are for repair, replacement, or scheduled maintenance. Each job ticket also includes detailed cause and remedy codes to pinpoint issues and provide effective solutions. Resources are carefully assigned to each task, and materials used are tracked to optimize inventory levels and reduce purchasing costs.

maintenance task management

By accurately monitoring labor hours, costs, and the progress of maintenance tasks, businesses can identify areas for improvement, allocate resources effectively, and make informed decisions to optimize their maintenance processes. This ensures that tasks are completed on time and within budget and reveals any potential bottlenecks or inefficiencies in their maintenance workflows.

![]()

Using Sage X3's Preventive Maintenance solution can improve efficiency, reduce costs, and increase profitability. Companies can streamline operations, minimize downtime, and optimize inventory levels by effectively managing equipment, resources, job tickets, and maintenance tasks. Contact us for more information on how Sage X3's Preventive Maintenance solution.