Whether it’s the conditions brought on by unforeseen circumstances, typical market saturation, or an evolution of organic business development, sometime during the lifespan of a manufacturing company, it may become imperative to diversify your offering to keep your business growing. Even established manufacturers with a solid foundation and loyal customer base may find that horizontal expansion is the driver they need to propel their business forward. In the case Ford Racing engine manufacturer, Roush Yates Engines, horizontal growth came as an evolution of their own internal expansion.

Roush Yates started with a small machine shop within their engine assembly plant to fabricate the prototype parts needed for their engines. The quick turnaround and technical precision that they were able to maintain within their own plant enabled them to get the exact parts they needed in a condensed timeframe. “Our objective was to reduce lead time and cost, while ensuring our proprietary information was safeguarded.” says Mary Ann Mauldwin, COO, Roush Yates engines. Over time they grew the process until they were making over 40% of their required parts in-house. As Roush Yates reputation for in-house fabrication grew, they were asked by other race teams to make parts for their engines, allowing their machine shop to grow large enough to move into its own facility. At this point, horizontal expansion became a priority.

»Thinking about growing your business horizontally? Download our Cheat Sheet

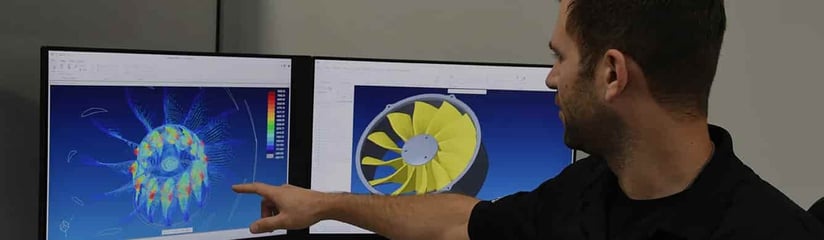

After adding additional machines and resources to their machine shop to accommodate the growing demand for engine parts, they needed to optimize the use of the proprietary CNC equipment used in part fabrication. Out of that need grew Roush Yates Manufacturing Solutions. While rooted in motorsports, Roush Yates Manufacturing Solutions has leveraged their technical expertise in CNC manufacturing into machining components for the aerospace, defense, medical, industrial, and automotive industries.

“I would recommend that manufacturers clearly define their goals before trying to diversify. If they are trying to create work for excess capacity, focus on customers/industries requiring the equipment and skills you have. If you start without this criteria, you will spend valuable resources quoting and programming only to find you can’t be profitable.”

When a manufacturer is planning to grow horizontally, it’s essential to completely commit to each of the additional industries that they plan to compete in. Roush Yates quickly found that some time and cost-intensive certifications were critical to achieving their goal to compete in the aerospace and defense industries. AS9100 certification for quality assurance in design, development, production, installation and servicing of aerospace equipment, for example, can take upwards of 6 months and tens of thousands of dollars to obtain. Additional certifications and standards by other industry regulating bodies such as the National Institute of Standards and Technology (NIST), and The International Traffic in Arms Regulations (ITAR) take even more resources to implement. “We were not interested in being a job shop. We wanted to use our experience in making complex engine parts to justify purchasing more complex equipment.” Mauldwin explained, “AS9100, NIST, ITAR, etc. are required, not recommended for these applications.”

Regarding physical expansion, Roush Yates found it more beneficial to their evolving needs to build out the machine shop before expanding their offering into a new customer base. This strategy gave them the opportunity to define the type of work to target i.e., material, part size, geometry and part tolerances. However not every company has the capital to invest in building out physical infrastructure before securing customers in the new industry and there are downsides to this model. While expanding the machine shop allowed Roush Yates to continue scaling orders for existing customers, focusing on physical expansion first limited their ability to use work cell concepts for the new industries (relocating 20,000lb machines isn’t easy or inexpensive) and limited their customer base somewhat due to the equipment choices that they made as they grew. Some manufacturers may find it more strategic to start contracting work before building out physical infrastructure and this should be considered carefully in a strategic growth plan.

For Roush Yates, growing their business into other markets was a natural extension of growing their existing offering but the decision still required strategic planning, research and commitment. Achieving successful horizontal growth doesn’t come easily or without tremendous amounts of planning and effort and it is critical to review key business areas before starting your growth plan.

Want to know whether your existing software infrastructure is up to the task? Schedule a software review with our team.

Want to learn more?

Read the blog: Business Intelligence for Modern Manufacturers

Watch the webinar: Current Challenges Facing Modern Manufacturers

Customer Success Story: Roush Yates Engines