Prior to V12, Sage X3 would not allow you to add or exclude components in a Work Order for a Version-managed Product. You could only make changes to a few fields, such as Scrap factor, Pick list and Requirement date fields.

Previously the process to accomplish this was to create a new bill of material version with the required changes and create a new work order, because the manufacturing process for version-managed products is normally tightly controlled.

This enhancement was made because: There are times when it is necessary to adjust the components on a work order for version managed products and the previous process was very cumbersome.

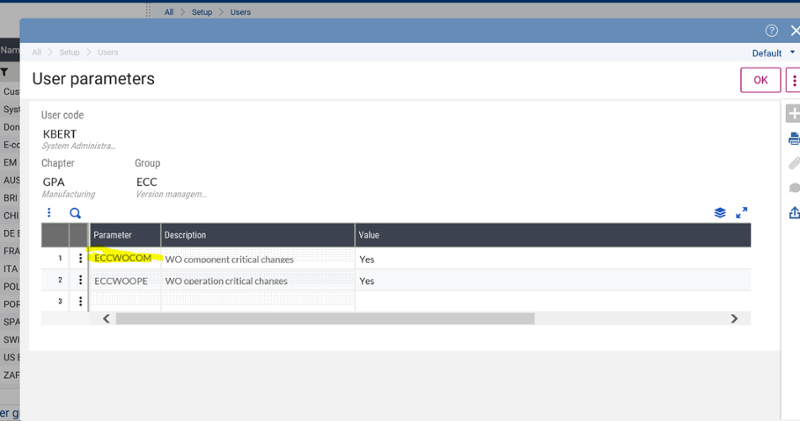

Now a user that has User parameter ECCWOCOM set to Yes, can make critical changes on components on work orders with version-managed products.

These changes include:

- Adding sub-assemblies (phantoms) and unexpected materials.

- Excluding/reactivating components

- Changing values on some fields – Required quantity, Operation number and Pick list code.

Other Enhancements include:

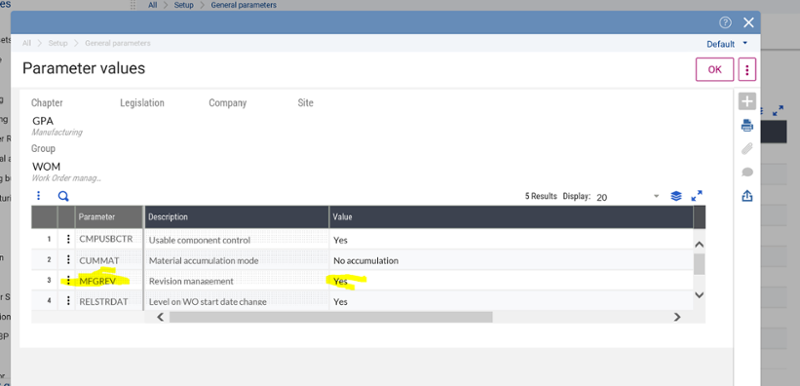

- The option to trace (parameter MFGREV = YES) critical changes (see below)

- The changes use the same work order statuses as work orders with non-versioned products

- You can only make the critical changes if Routing WO Management = ‘Materials change’ or Change Materials and operations’

Benefits:

- Saves time when a change is required

- May lead to increased productivity

- You can trace the changes

- Simplifies processes which can reduce costs

When the MFGREV parameter for Revision Management is set to YES:

- You will need to add a reason for each change

- The revise history for each critical changed will be recorded in the MFGMATREV table when the Work Order is saved.

- You can then review the revision history for each component line.

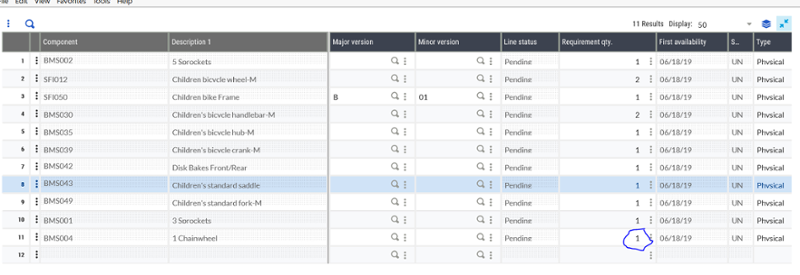

Now let’s try making a couple of these changes to a version managed Work Order.

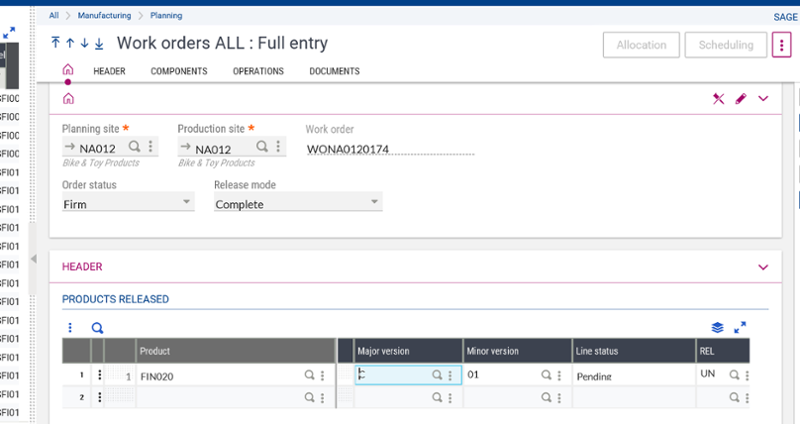

Create a new Work Order for a version-managed product:

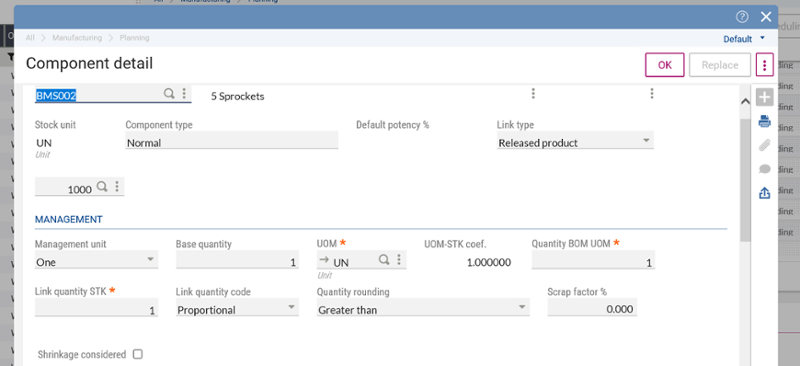

Add the component.

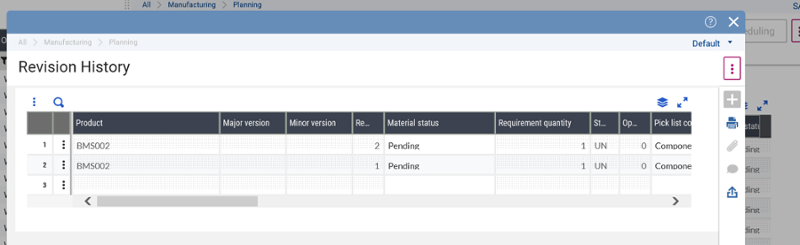

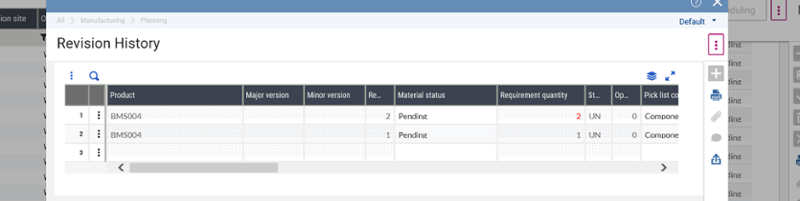

In the action button on the new component line – choose Revision History – now you can see the change that was made.

Now let’s change a requirement qty from 1 to 2.

Look at line 11 – it has been changed from 1 to 2

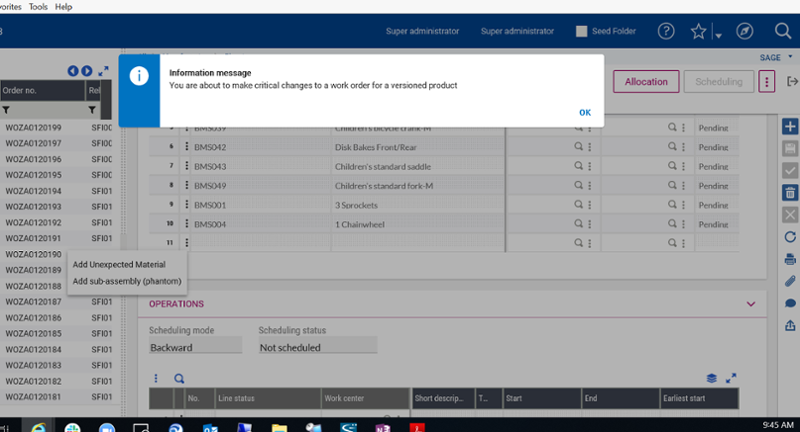

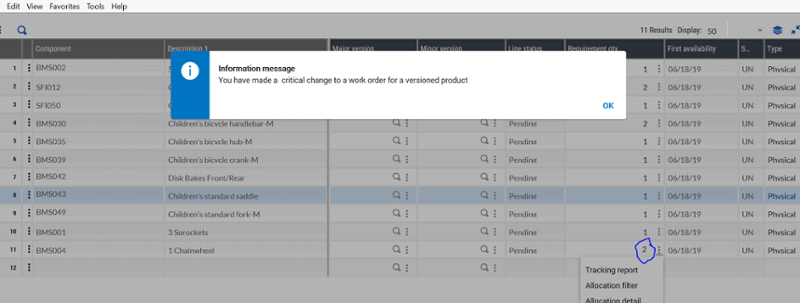

You will get the message below, just click ok.

Again, if you click on the component line that you just changed and choose Revision History, you can see the changes you made.

Now you have seen how you can make changes to a Versioned Work Order.